Control Panel Label Materials FAQs

10 mil Lexan® Matte or Velvet Polycarbonate is ideal for professional-grade overlays and nameplates. It offers excellent dimensional stability and subsurface printing protection, though it requires adhesive lamination.

Yes. 10 mil LexSaver® Plus Vinyl and LexSaver® Plus Polycarbonate are designed for outdoor applications and resist UV, abrasion, and weather for up to 5 years.

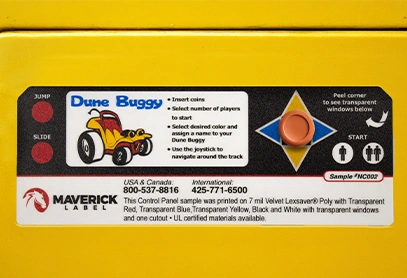

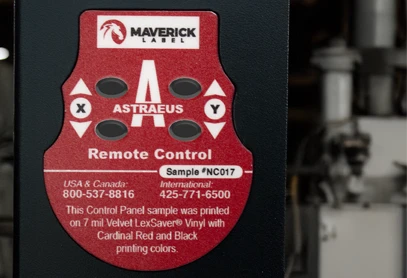

LexSaver® Vinyl and LexSaver® Polycarbonate (7 mil) include adhesive backing, making them easier to apply to a variety of surfaces without additional lamination steps.

LexSaver® Plus Vinyl and LexSaver® Plus Polycarbonate (10 mil) are optimized for both indoor and outdoor conditions, offering high resistance to UV exposure, scratching, and wear.

Absolutely. All Lexan® and LexSaver® materials support subsurface printing, which protects your graphics from wear, chemicals, and environmental exposure.

- Lexan® is a premium polycarbonate film that requires applied adhesive and is not rated for outdoor use.

- LexSaver® includes adhesive and comes in outdoor-rated options, making it more versatile for different surfaces and conditions.

Yes. Materials like Velvet Lexan® and Velvet LexSaver® offer a lightly textured surface for added tactile appeal and reduced glare.

7 mil LexSaver® Polycarbonate has a stretch resistance rating of 5, offering excellent durability for dimensional stability and wear resistance.

Key factors include:

- Application surface (flat vs. uneven)

- Indoor or outdoor exposure

- Need for subsurface printing

- UV, abrasion, and chemical resistance

- Permanent vs. removable adhesive backing

Label clarity, color coding, and strategic placement can make even the most complex systems intuitive. See real examples in our blog: Is Your Control Panel Too Complicated for the User?

Add-on panels are frequently used in HVAC systems, manufacturing automation, and custom machinery. Learn more in: What is an Add-On Control Panel Used For?

Start by mapping your components, selecting the right materials for overlays, and choosing durable label adhesives. Read the full guide: How to Create a Custom Control Panel?

The electronics industry follows strict procedures for surface prep, application pressure, and curing time. See best practices in: Label Application Procedure in the Electronic Industry.