Equipment Label Materials FAQs

Standard 4 mil Vinyl – Gloss White is an economical and flexible choice for most indoor and moderate outdoor uses. It’s compatible with all printing colors and foils and conforms to slightly irregular surfaces.

Vinyl Elephant Grip and Polyester Elephant Grip are specifically designed with aggressive adhesives that bond securely to LSE plastics and powder-coated finishes.

Removable 4 mil Vinyl is designed for temporary labeling. It can be cleanly removed from most surfaces within 6 months without leaving residue.

Convex Vinyl (4 mil or 6 mil) is engineered to conform to rounded shapes such as helmets, pipes, or hard hats. Also available in high-gloss silver foil for premium finishes.

Yes, Security VOID Polyester and Destructible Reflective Vinyl are designed for tamper-evidence. VOID materials show clear removal marks, while destructible vinyl breaks apart upon tampering.

- Reflective Vinyl: Up to 7 years

- Premium 2 mil Vinyl: Up to 5 years

- Convex Vinyl: Up to 2–5 years

- Destructible Reflective Vinyl: Up to 7 years

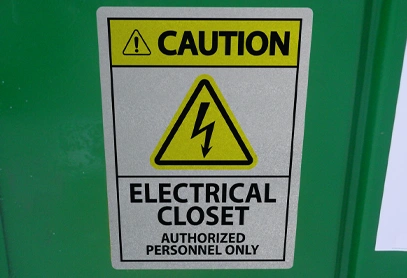

Polyester 2 mil and Polyester Elephant Grip offer heat resistance up to 302°F. They’re ideal for industrial equipment and electrical panels.

Yes, Fluorescent Vinyl (4 mil) offers bright colors for low-light environments, and Reflective Vinyl (7.5 mil) ensures high visibility day and night.

Yes. Lexan® Matte and Velvet 10 mil are great for graphic overlays and membrane switchpads, offering subsurface printing for maximum durability.

Yes, many materials like Premium Vinyl, Polyester, and Reflective Vinyl are rated for 2–7 years of outdoor use. Lexan® is not recommended for outdoor applications due to yellowing.

Absolutely. Most materials accept all our printing colors and foils. For metallic or transparent designs, undercoats like white primer are recommended.

Premium Vinyl (2 mil) and Polyester 2 mil provide high-resolution print quality for barcodes, serial numbers, and small text.

Yes. PVC (10 mil) is semi-rigid and great for indoor tags, door signs, or hanging permits. Lexan® is ideal for overlays or protective graphic panels.

Polyester and Lexan® materials have the highest stretch resistance (rated 5), ensuring stability and durability over time.

- Environment (indoor/outdoor, heat, moisture)

- Surface (flat, curved, LSE plastics)

- Adhesion (permanent, removable, aggressive)

- Visibility (reflective, fluorescent, color)

- Security (tamper-evident, destructible)

- Durability (years in service, temperature range)

Visit our Industrial Safety Labels page to explore OSHA-compliant materials designed to withstand extreme conditions and improve workplace safety.

From material strength and adhesion to environmental resistance and compliance markings, our blog breaks down everything you need to know in the Key Features of Equipment Labels guide.

Yes. We offer labels that meet industry requirements for plug conformity, ensuring safety and traceability. Learn more in our article: Using the Right Plug with Conformity Labels.

Understanding terms like “face stock,” “adhesive types,” and “laminate” helps in choosing the right solution. Check out our Easy Guide to Label Terminology for clear definitions.

Permanent labels reduce errors, enhance traceability, and withstand harsh environments—especially in manufacturing and logistics. Read the full blog: Improve Safety and Efficiency with Permanent Labels.

Circuit boards require heat-resistant and non-conductive labels. Check our recommendations in: The Best Circuit Board Labels for Industrial Use.

Yes. Some polyester labels are tested to withstand over 300°F, making them suitable for harsh heat exposure. See extreme use cases in: Labels That Resist Blow Torch Heat.